AMED s.r.l.

uses Additive Manufaturing (AM) techniques for

Design

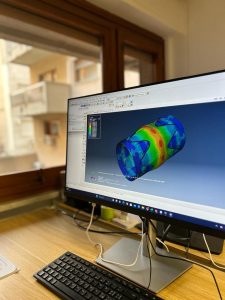

The workflow, which AMED applied to realize custom made products, guarantees short delivery time thanks to the modern technologies adopted. Design of custom implants requires a close collaboration between AMED and surgeon. DICOM images obtained from patient’s CT scan are necessary to obtain the virtual model of the internal structure of the body. AMED provides the surgeon with a CT scan protocol, including an appropriate CT scan parameters setting and examples for correct imaging of different regions of interests. DICOM images are then processed to create the 3d anatomical model and the implant model is created making use of the computer-aided-design software, by mirroring, if possible, the healthy body side, to ensure optimal aestethics of prostheses, especially cranio-maxillofacial prostheses. After surgeon approved implant design, final CAD model is then converted for printing process.

Manufacturing

Technologies adopted by AMED are:

1. Selective Laser Melting (SLM), by means an high energy - produced from a laser source - melts metallic powder, according to geometrical data contained in a 3D computer aided design (CAD) file, which is sliced into layers with a defined thickness.AMED uses Print Sharp 150 and Print Green 150 as printing techniques, and a cutting edge machine that allows the creation of complex geometries thanks to a precision of a single line width of 0.1mm and a minimum layer thickness of 0.02mm.

2. Stereolithography (SLA), a 3D printing technology to produce photopolymer parts, by using a projected UV light source to cure the resin into a solid layer by layer, therefore creating a three-dimensional structure. AMED uses Form 4B printer, which delivers production-quality design prototypes and end-use products with very smooth surfaces.

3. Selective Laser Sintering (SLS) is a 3D printing technology that uses a laser to sinter material powders, binding them together to create a solid object. SLS is highly valued for its ability to create complex geometries without the need for supports, making it ideal for the production of functional prototypes, mechanical components, and final production parts with excellent mechanical properties. Commonly used materials include nylon, metal powders and composites, offering a wide variety of options for different industrial applications.

Materials

Ti6Al4V ELI (Grade 23) is an alpha + beta alloy with extra low interstitial elements (O, N, C). It guarantees high strength and long-term bone bonding. Furthermore it has low weight ratio, excellent biological compatibility, higher corrosion resistance, non-magnetic properties and high toughness.

Chromium-Cobalt (Co-Cr) is widely used in biomedical applications due to its excellent mechanical properties and corrosion resistance. It is also biocompatible, which means it does not cause adverse reactions when implanted in the body. This is crucial for applications such as joint replacements and dental implants.

Wide range of resins for 3D printing offering an extraordinary range of possibilities, from engineering to custom design to be used in dental applications. Resins are liquid materials that solidify through a photopolymerisation process, usually using UV light. This allows the creation of fine details and smooth surfaces, making resins ideal for high-precision prototypes. There is a world of different resins, each with unique properties: from standard resins for rapid prototyping, to hard resins for functional parts, to biocompatible resins for medical applications.

PA2200 is a form of polyamide, commonly identified as Nylon. Widely used in a variety of industrial contexts and applications, PA2200 stands out as a versatile material due to its exceptional mechanical and chemical properties. Its characteristics are amplified by the possibility of 3D printing using SLS technology, allowing us to produce applications, prototypes or entire production batches.

This material is characterized by several key features that make it a remarkable material in production, such as:

- High Resolution and Selectivity: remarkable detail resolution and high selectivity, ideal for creating parts with precision.

- Strength and Rigidity: Sintered PA2200 parts have an excellent combination of strength and rigidity, providing mechanical strength and adaptability.

- Chemical Resistance: The material offers good resistance to chemicals, expanding its potential applications in various industrial contexts.

- Biocompatibility: Approved for use in medical devices and other applications requiring biocompatible materials, such as orthopaedic components.